Screen printing vs. heat press: Regarding custom apparel, which method is the perfect fit for your unique designs? Choosing between these two techniques can be a challenging decision. Do you prioritize vibrant colors, durability, or cost-effectiveness? This comprehensive analysis dives deep into custom printing, exploring the differences, advantages, and ideal scenarios for both screen printing vs heat press. By the end, you'll clearly understand which method best fits your specific needs and audience.

So, let us learn about screen print t-shirts in the below parts:

- Part 1: What is Screen Printing

- Part 2: Cost Comparison

- Part 3: Result Comparison

- Part 4: Steps Comparison

Part 1: What is Screen Printing

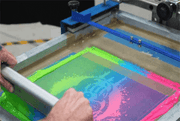

Screen printing is a famous method for transferring images and designs onto fabric, particularly for screen print T-shirts and promotional items. This age-old technique involves creating a stencil on a mesh screen and using ink to transfer the design onto the material. Each color in the design needs a separate screen, making it ideal for simpler designs with few colors.

One of the standout features of screen printing is its durability. The ink used in this process becomes a part of the fabric, ensuring that the design can withstand numerous machine washes, often lasting for the garment's life. This long-lasting quality makes it a preferred choice for items that will see regular use.

However, screen printing does have its limitations. It is best suited for simpler designs and unsuitable for complex, multi-colored graphics. Setting up the equipment for screen printing can be more time-consuming and may require higher minimum orders, making it less suitable for small quantities.

In choosing Screen Printing vs Heat Press, here are some tips. If you prioritize durability vibrant colors on darker fabrics, and are printing a larger order of the same image, screen printing is likely the better choice. On the other hand, a heat press may be the way to go if you need a cost-effective solution for smaller quantities or complex, colorful designs. Consider your audience and the nature of your project to make the best choice.

Part 2: Material Comparison Between Screen Printing vs Heat Press

The cost is a significant factor when deciding between Screen Printing vs Heat Press. The materials required for each method vary, and it's important to know what you need to prepare for screen printing, including the heat press machine.

Screen Printing Costs:

- Screen and Emulsion: To begin screen printing, you'll need screensand emulsion. Screens are typically reusable, so the initial cost is relatively low. The emulsion creates stencils on the screens.

- Ink: High-quality screen printing ink is essential for vibrant and lasting prints. The cost of ink can vary based on the number of colors and the quantity you need.

- Squeegees: Squeegees apply the ink to the screens. They are relatively inexpensive and reusable.

- Dryer: A conveyor dryer cures the ink on the fabric. Dryers can be a significant investment but are crucial for large-scale production.

- Heat Press Machine: While a heat press machine is not typically for screen printing, it may be necessary for specific applications, such as curing certain inks.

Heat Transfer Costs:

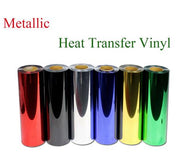

- Heat Transfer Vinyl (HTV): HTV comes in rolls or sheets, and its cost varies depending on the color and type of vinyl. For multi-colored designs, you'll need multiple vinyl colors.

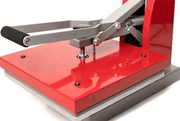

- Heat Press Machine: This machine is an essential tool for heat transfer. The cost of these machines can range from affordable for basic models to more expensive for commercial-grade options.

- High-Quality Paper: You'll need special paper with solvent ink compatibility for digital print heat transfer. This paper produces high-resolution images.

- Weeding Tools: When using vinyl heat transfer, you'll require weeding tools to remove excess vinyl material from the design.

To learn the full preparation of heat press sublimation, read this article:

A Beginner Tutorial on How to Sublimate a Shirt the Best!

Screen printing is cost-effective for larger quantities of the same design. The initial investment in screens and equipment can be higher, but per-unit costs decrease with larger orders. Heat transfer is more cost-effective for smaller quantities and designs with multiple colors. The cost of vinyl and heat press machines may be lower upfront, but per-unit costs can increase for larger orders.

It's essential to consider the volume of your order and the complexity of your design when choosing between these methods. Heat transfer might be the more affordable choice if you have a small order with a complex design. For large orders of the same design, screen printing offers cost savings. Additionally, the choice of material and including a heat press machine will depend on your specific method. Your decision should align with your budget and the needs of your target audience.

Part 3: Result Comparison Between Screen Printing and Heat Press

Let's delve into the differences between Screen Printing and Heat Press methods and showcase some examples.

- Texture:

The screen printing method results in a softer feel on the fabric. The ink becomes an integral part of the fabric, offering comfort and a lasting, durable finish. It's perfect for creating T-shirts with a classic, comfortable feel that stands up well to frequent use and washing.

In contrast, heat pressing provides a smoother finish, but the fabric may feel slightly stiffer than screen printing. While it may not offer the same level of softness, it gives your designs a neat and smooth surface.

- Color Brilliance:

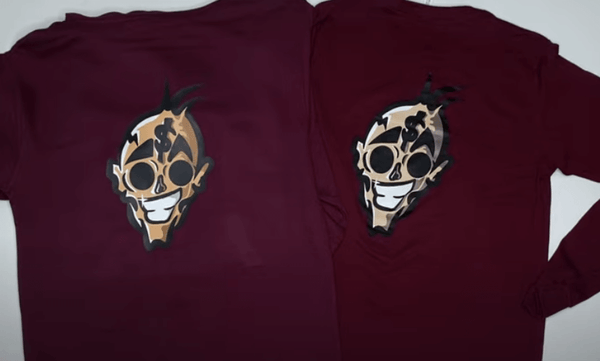

Screen printing is renowned for producing vivid and vibrant images, even on dark-colored fabrics. The colors stand out vividly, making it an excellent choice for creating eye-catching designs.

Heat pressing allows you to use multiple colors, making it an ideal choice for intricate and colorful designs. This method excels in achieving high-resolution, intricate patterns and photo transfers.

- Versatility:

Screen Printing: Screen printing is highly versatile and can work on various materials. It's not limited to just T-shirts; it's suitable for various substrates, including wood, plastic, leather, and more. This versatility makes it a popular choice for creating branded promotional items.

Heat Press: Heat press is not limited to fabric but is highly suitable for fabric and a wide range of other substrates. It offers flexibility in working with different materials, expanding its application beyond apparel.

- Durability:

Screen printing yields highly durable graphics. The ink becomes an integral part of the fabric, making it resistant to fading and cracking, even after numerous washes. This durability ensures your designs remain vibrant and intact over time.

Heat press designs are durable, but their longevity may not match screen printing, especially with frequent washing. While they hold up well, they might show signs of wear with extended use.

- Print Appearance:

Screen Printing: Screen printing offers a classic, timeless look that many people associate with quality and durability. It's perfect for creating traditional and long-lasting designs.

Heat Press: Heat press is ideal for achieving intricate, detailed designs, including photo transfers. It provides a modern, vibrant, eye-catching, and visually appealing appearance.

Heat Press Screen Printing

- Environmental Impact:

Traditional screen printing ink may not be as environmentally friendly, but choosing eco-friendly options is possible. Depending on ink choices, screen printing can be adapted to be more sustainable and ecologically responsible.

Heat press printing can be eco-friendly, especially when using phthalate-free inks. It works and dries like conventional dyes but with a greener approach, making it a conscious choice for those concerned about the environment.

The choice between screen printing and heat pressing affects the outcome of your project. Screen printing produces softer, durable prints with vibrant colors, making it versatile for various applications. Heat pressing offers environmental benefits, versatility in color usage, and ease of setup. The choice should align with your project's requirements, whether you prioritize durability, color vibrancy, or environmental considerations.

Examples of screen printing results include T-shirts with bright and soft designs, while heat press results may involve intricate, colorful graphics with photo transfers. Your choice should reflect your desired outcome and the materials you intend to print on.

Part 4: Steps Comparison

The heat press process is significantly faster and requires fewer steps, making it an efficient choice, especially for small orders and quick turnarounds. It's an excellent option for those who value simplicity and speed in their printing projects.

For Screen Printing:

Step 1: Create the Design

First, make the picture or words you want to print.

Step 2: Prepare the Screens

Cover screens with unique stuff and shine light through the design, like a stencil.

Step 3: Print the Design

Use a special machine to press ink onto your clothes, one color at a time.

Step 4:Dry and Check

Heat the clothes to make the ink stick, then check if it's good.

For Heat Press:

Step 1: Choose the Design

Pick the picture you want on your clothes.

Step 2: Print the Design

Print your chosen picture on special paper.

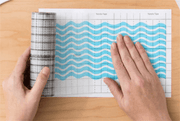

Step 3: Set up the Clothes

Lay your clothes flat and smooth.

Step 4: Press and Finish

Put the printed paper on your clothes and press it with a machine. The picture sticks, then wait a few seconds before peeling off to reveal your design. And you're done!

And this is the heat press used in the video:

Free Your Hands with HTVRONT Auto Heat Press

- Heat up to 320℉ /160℃ within 4 mins, saving 2minutes than common type.

- Upt to 4 fast modes, 2 custom modes and an auto mode for your creativities.

- Separated ironing board and auto shut-down design for your safety.

Part 5: Summary

So, guys, the choice ultimately comes down to your unique needs and preferences. If you prioritize vivid and durable designs, particularly for larger quantities of the same image, screen print t-shirts are the traditional, reliable choice. Heat press, on the other hand, offers quick, versatile, and eco-friendly printing solutions, ideal for smaller orders with intricate designs.

In deciding between Screen Printing vs Heat Press, It's essential to consider factors like budget, the complexity of your design, and your target audience when making the decision. Each method has advantages, and your selection should align with the desired outcome for your custom apparel.

![[Starter Kit] Auto Heat Press Machine 15" x 15" 110V + Starter Kit Bundle](http://www.htvront.com/cdn/shop/files/20240425-170634_385x.jpg?v=1714036345)

![[Premium Bundle] Auto Heat Press Machine 15" x 15" 110V + 20 rolls HTV Bundle 12“x3ft + Mini 2 Heat Press Machine + Random Sublimation & HTV Bundle ≥ $180](http://www.htvront.com/cdn/shop/files/1UK_4_22c12b1b-12dd-4105-ac25-93e2faae6a8c_385x.jpg?v=1713863580)