Explore the cutting-edge direct-to-film transfer paper printing technique, a versatile and vibrant method revolutionizing the print industry. Unlike traditional methods, DTF allows you to create stunning designs on various fabrics, from classic cotton to tougher materials like polyester, nylon, and fleece. With its exceptional color vibrancy and intricate detailing capabilities, DTF is becoming the preferred choice for producing personalized clothing, promotional products, and more.

So, let us delve into this comprehensive guide on DTF transfer paper printing techniques in the following parts.

Part 1: What’s DTF transfer?

Part 2: Is DTF transfer for you?

Part 3: How to do DTF transfer step-to-step?

Part 4: Summary and FAQs

Part 1: What’s DTF transfer?

DTF transfer, also known as "direct-to-film" transfer, is a cutting-edge printing technique that enables the transfer of complex and vibrant graphics onto different fabric types. You print a design using water-based inks and a particular powder adhesive onto a specific PET film. Bright, finely detailed images get produced by applying heat and pressure to the printed pattern before it gets transferred to fabric.

Before beginning the DTF transfer process, several crucial components must be ready:

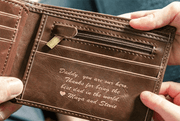

- Design Creation: Begin by crafting your design digitally, ensuring its intricacies and colors are well-suited for the DTF transfer process.

- DFT Transfer Paper: Purchase a good-qualityDTF transfer paper to give your design a great outcome.

- PET Film and Inks: Select a high-quality PET film designed for DTF printing and compatible water-based inks. These inks are formulated to bond effectively with the fabric and PET film.

- Special Powder Adhesive: Acquire the appropriate powder adhesive that complements the chosen PET film and inks. This adhesive enhances the bond between the printed design and the fabric during heat transfer.

- Fabric Selection: Choose the fabric you intend to transfer the design onto. DTF printing works well on fabrics like cotton, polyester, and blends.

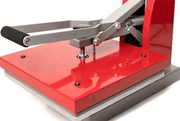

- Heat Press Machine: Invest in a reliable heat press machine that ensures proper heat and pressure application during transfer. This is crucial for achieving optimal adhesion and color vibrancy.

- Temperature and Pressure Settings: Fine-tune your heat press machine's temperature and pressure settings according to the fabric and materials you're using. Precise settings contribute to successful transfers.

DTF printing provides unmatched color vibrancy, fine detailing, and versatility on various fabrics. You may use direct-to-film transfer paper to produce customized apparel, promotional goods, and more with a stunning aesthetic impact by combining the correct design, supplies, and tools.

Part 2: Is DTF transfer for you?

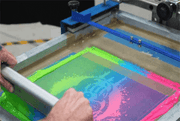

DTF Transfer develops as a strong competitor to established methods like vinyl heat transfer and screen printing. Let's see how it compares to these techniques to decide if DTF Transfer Printing is the best option for you.

DTF Transfer Printing has distinct advantages over screen printing and vinyl heat transfer.

- Design Complexity: Unlike Vinyl Heat Transfer, which can only handle simple designs, DTF Transfer Printing brings complex and detailed full-color designs to life.

- Comfort and Feel:Compared to the occasionally heavier and stiffer results of vinyl heat transfer, the completed products of DTF Transfer Printing claim a gentler and lighter feel on garments. This improves wearers' comfort.

- Longevity and Durability:Unlike Vinyl Heat Transfer prints, which may peel and break over time, DTF Transfer Printing promises durable prints that won't crack or peel. Even the strong reputation of screen printing cannot match this durability.

Pros of DTF Transfer

- Color Variety: DTF Transfer Printing outperforms Screen Printing by providing a limitless number of colors in a single pass, eschewing the limitations of many screens.

- Quickness and Efficiency: DTF Transfer Printing's rapid setup and printing times beat screen printing's labor-intensive procedure and vinyl heat transfer's need for cutting and weeding.

- Eco-Friendly: DTF Transfer Printing is known for producing little waste and using fewer chemicals.

- Design Complexity: DTF transfer paperprinting is an excellent option for designs with complicated details and brilliant color reproduction.

Cons of DTF Transfer

- Equipment Cost: Specific equipment is needed to set up DTF Transfer Printing, which may demand an initial outlay of funds.

- Learning Curve: Switching to DTF Transfer Printing may require a learning curve to understand the procedures and get the best results.

DTF emerges as a dynamic and versatile superhero since it can deliver vibrant, intricate designs on various fabrics. It gives faster turnaround times and an eco-conscious approach position. This makes DTF transfer printing a formidable choice for those seeking to elevate their printing game. So, if you are in personalized clothing, promotional items, or creative projects, DTF transfer paper printing can be the hero.

Top of Form

Part 3: How to do DTF transfer step-to-step?

DTF transfer is a creative printing technique that lets you print vivid patterns on cloth. Let's go over the DTF transfer procedure step by step, with thorough settings and justifications for each action:

Step 1: Prepare the design

Create a fabric design before anything else. You may create this utilizing online resources or graphic design software. Verify that the design is DTF technology compliant.

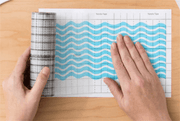

Step 2: Setting up a heat press and pre-pressing the fabric.

Start by warming up the film in the heat press. Insert the fabric into the heat press that will bear the design. Keep it heated for 2 to 5 seconds to dehumidify and pre-flatten it.

Step 3: Applying the Design

Carefully place the heated film over the pressed fabric.

Close the heat press and set it to a temperature of roughly 165°C (329°F) for heat transfer. Heat and apply pressure for 15 to 20 seconds. Remember that these settings may change depending on the individual film and cloth you're using, so pay attention to the manufacturer's suggestions.

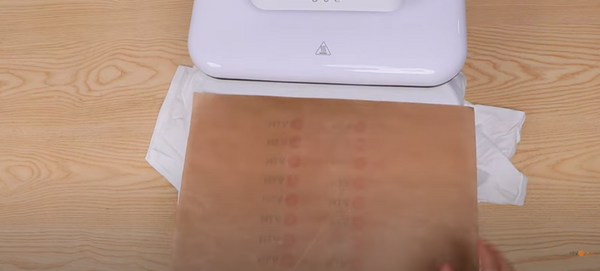

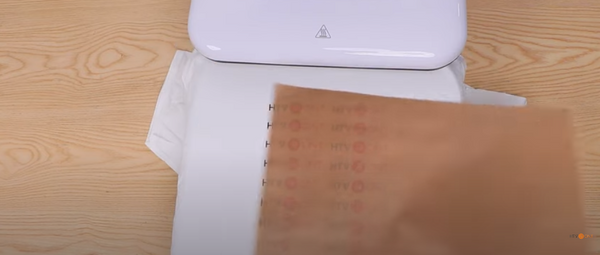

Step 4: Post-Pressing and Peeling

Gently peel the film away from the cloth after the heat transfer. This process is called cold peeling.

Reposition the cloth with the transferred design in the heat press to increase the longevity of the design. Close the press and exert light pressure briefly, often for 5 to 10 seconds.

Step 5: Finishing Touches

Your DTF transfer is almost ready!

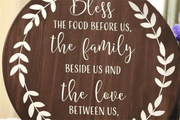

Your fabric is ready to be packaged and dispatched to clients after the post-pressing is complete. The end product is an eye-catching and intricate design.

DTF transfer offers an exciting way to bring your designs to life on fabric. With the right steps and attention to detail, you can create stunning, durable, and vibrant printed garments using this technique.

Part 4: Summary and FAQs

Thus, we hope you understand how to use the DTF transfer paper printing technology to create vivid and elaborate graphics on various materials. This adaptable approach challenges conventional printing methods and provides countless color possibilities, quicker output, and environmental friendliness. So, try out the Direct to Film transfer paper printing right away. It can be your entryway to remarkable designs in the custom apparel and promotional items markets.

FAQs:

Q1: What is printing on DTF transfer paper?

A: A cutting-edge technique called DTF transfer paper printing uses specialized film, water-based inks, and heat press equipment to print detailed and vibrant graphics on fabrics.

Q2: How does DTF stack up against other printing techniques?

A: DTF transfer outperforms screen printing and vinyl heat transfer. It delivers brilliant images while providing limitless color possibilities, speedier setup, and environmental friendliness.

Q3: What do I need to print on DTF transfer paper?

A: Choose a fabric, create a digital design, buy high-quality Direct To Film transfer paper, appropriate PET film, water-based inks, and heat press equipment. Adjust the pressure and temperature settings.

Q4: Is printing on DTF transfer paper appropriate for intricate designs?

A: Yes. Unlike more straightforward techniques like vinyl heat transfer, DTF transfer paper printing brings complex and detailed full-color graphics to life on fabrics.

![[Starter Kit] Auto Heat Press Machine 15" x 15" 110V + Starter Kit Bundle](http://www.htvront.com/cdn/shop/files/20240425-170634_385x.jpg?v=1714036345)

![[Premium Bundle] Auto Heat Press Machine 15" x 15" 110V + 20 rolls HTV Bundle 12“x3ft + Mini 2 Heat Press Machine + Random Sublimation & HTV Bundle ≥ $180](http://www.htvront.com/cdn/shop/files/1UK_4_22c12b1b-12dd-4105-ac25-93e2faae6a8c_385x.jpg?v=1713863580)